Products

Wire Rope Lubrication Systems That Generate the Highest Level of Internal Pressurization and Coating Performance

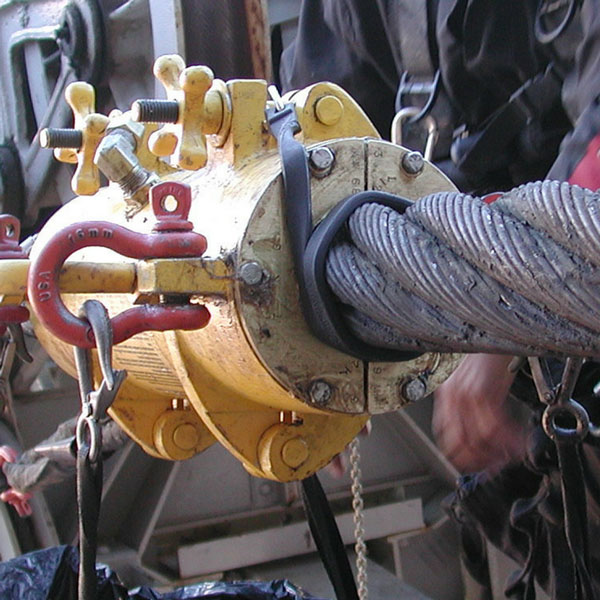

In only one application, wire rope can have its surface and groove pattern scraped clean of product buildup and debris. At the same time, new lubricant is uniformly applied to the newly cleaned wire rope surface and groove pattern. Pressurized coating product then fills any open spaces within the groove pattern and internal strands that are open to receive it. This is accomplished as the wire rope passes through a controlled, 100% pressurized immersion within the internal seal lubrication chamber. Surface moisture trapped within the internal strands is displaced and replaced with the newly applied wire rope coating product. Kirkpatrick Systems are functional with both low and high viscosity coatings. They can be incorporated as a grease applicator for tough working environments where higher viscosity coatings are required to fight friction wear due to strand rubbing, as well as a low viscosity oiling system required for certain cable cleaning & lubrication applications. The Kirkpatrick Group’s lubrication systems offer all of these benefits to keep your wire ropes cleaned and lubricated ensuring dependable performance and longevity.

Kirkpatrick Manual Strippers – Wire Rope Groove Cleaners

An optional manual stripper is available to be used as a rotational base for specially designed helix wire rope groove cleaners. This option allows users the capability to surface clean the wire rope separate from the lubrication process. Once cleaned, an unhindered visual inspection can then be performed to determine the wire rope’s condition prior to servicing or in-between service dates. This process is much more effective than using a labor-intensive cable brush cleaner that incorporates individual wires that easily gum up and require frequent cleaning.

Our Available Configurations for Lubrication Systems

Your equipment deserves the best cleaning and maintenance to keep it in top condition, including the wire ropes you depend on for hoisting and moving materials. Kirkpatrick Wire Rope Lubrication Systems come in three basic configurations:

- Standard System: Accommodates wire rope diameters of 1/4″ (5mm-6mm) to 1-7/8″ (48mm)

- Jumbo System: Accommodates wire rope diameters of 3/8″ (9mm-10mm) to 4-3/8″ (110mm)

- Jumbo Internal Spray System: (Designed for the application of low viscosity, “oils” as well as high viscosity “low flow” coatings) JUL Systems accommodate wire rope diameters through 2-1/4” (57mm/58mm). (Low viscosities) and up to 4 3/8″

The Kirkpatrick Group Inc.

Serving Clients Worldwide

The Kirkpatrick Group Inc. has our products available to customers across the United States and overseas. With our international reach, we provide high-quality cleaning and lubrication products to keep wire ropes properly cleaned and maintained for a wide range of industries and applications. Contact us if you have any questions about our company and products, and place your order for wire rope lubrication systems today.