The Kirkpatrick Group Inc.

Dynagard™ Environmentally Safe Wire Rope Lubricants

Since 1982

Reviews

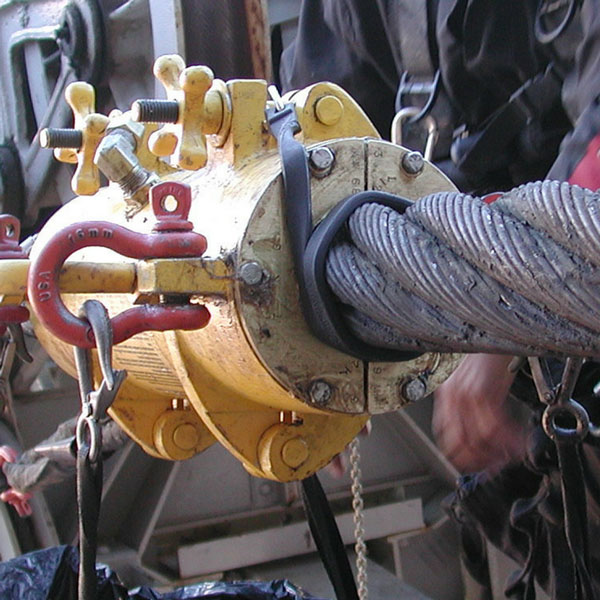

Manual Wire Rope Preventative Maintenance of all of the ships’ wires was taking a week to complete. Now, since receiving the Model SU35B Wire Rope Lubricator, the time to complete the project has been reduced to 1 day with fewer shipboard personnel involved.

Using the Kirkpatrick Model SU35B Wire Rope Lubricator and Dynagard™ Environmental Wire Rope Lubricants has increased their rope life from 2 – 3 years to 8 or 9 years. The job is now performed in one day over the 2 or 3 days it took previously.

Hello Bob, I tried your wire rope lubricator today for the first time and I can only say wonders about it. It has cut by 90% the time we have to spend on lubricating our skip hoist and it does a much better job than our old method of using rags.

Dynagard™ “E” Environmental Wire Rope Lubricant is still protecting his 3/4″ ropes after 6 years.

Brad used to be with the United States Coast Guard in Key West, Florida and used the Kirkpatrick SU35B Wire Rope Lubricator there. He said his crew used to laugh at other sources on the base who continued with hand maintenance for their wire ropes. They would take 10 hours to complete what he and his crew could do in 2 or 3 using the Kirkpatrick System.