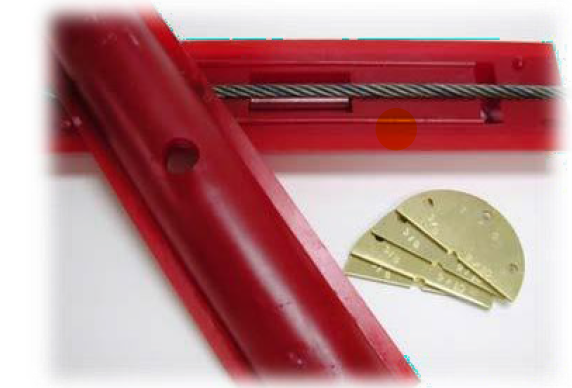

Seal & Scraper Plate Kits

Kirkpatrick Seal Kits consist of two specially formulated proprietary Polyurea Seal Halves. Seal Halves are engineered to fit neatly into the corresponding configured Lubrication Collar Halves. They also incorporate a 1 to 2-millimeter compression factor for those Wire Ropes that may be marginally larger than their rated Diameter.

Seal and Scraper Plate Kits work to remove excess corrosion and debris from the outer circumference of the Wire Rope as it enters the Lubrication Collar and then seal around the Wire Rope to allow for better penetration of the Wire Rope coating being applied. Scraper Plates also work to smooth new Lubricant as the Wire Rope travels from the Lubrication Collar.

There is no perfection regarding rated Wire Rope Diameters as opposed to their actual infield / under load Diameter. In most instances, though they can be very close.

However, a Diameter can become a fit factor when it involves larger Diameters such as 2 Inch (51mm) and above. As a matter of fact, there can sometimes be as much as a 1 to 4 mm variation for Wire Rope Diameters in the 80mm and above range.

Another influencing factor is the construction and the age of a particular Wire Rope. We have recently noted that some Wire Rope Manufacturers are now referring to a possible Diameter variance in their rated specifications. Knowing about these variances helps our users to understand that even though variances are not a strong factor in ordering Wire Rope; it is a crucial factor in providing the best fit possible for the components we supply with our Systems.

Testimonial

I am writing this letter to tell you how impressed we are with the longevity and durability of your Seal and Scraper Plates. We used ¾” set in 60,000 ft. of ¾ 6×19 Class IWRC that made up the topping purchase and Vang wires of deck mounted cargo booms on the Naval Reserve Ship USS – Comet. We fully expected to replace this ¾” Seal and Scraper Plate Kit after this job. This has not been the case. These Seals and Scraper Plates have given us years and approximately 100,000 ft. of extra service.”

Ed Swenson

Marine Sales Manager West Coast Wire Rope

Portland, Oregon