Misunderstood Aspects of Crane Rope Maintenance

Wire rope lubrication

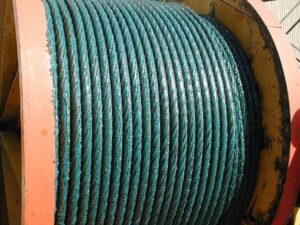

Among the most misunderstood aspects of crane rope maintenance is lubrication. When a wire rope is bent the individual wires and strands must slide relative to each other and the rope itself glides within the sheave. Without proper lubrication, friction increases, and the rope life is drastically reduced. Checking the lubrication and periodically applying a thin coating of maintenance lubricant is key to any maintenance program. As a rule of thumb, ropes require maintenance lubrication every six to 12 months.

When it comes to maintenance lubrication there are a few lesser-known things to keep in mind. First, the lubricant must be compatible with the original lubricant. Otherwise, through intermixing, the two products can form a totally different lubricant with different technical properties. Second, a lubricant designed only for wire rope is a must. Wire rope lubrication performs a very specific function with very specific properties which generally cannot be met by multi-use products such as a typical gear, chain, and rope lubricant. Third, the lubricant must be able to penetrate inside of the strands to cover each component uniformly. A product that just sits on the outside does not help the wire rope life, plus it can inhibit inspection .#ports #cranes #maintainence #lubrication #shippping #mining #offshore #marine